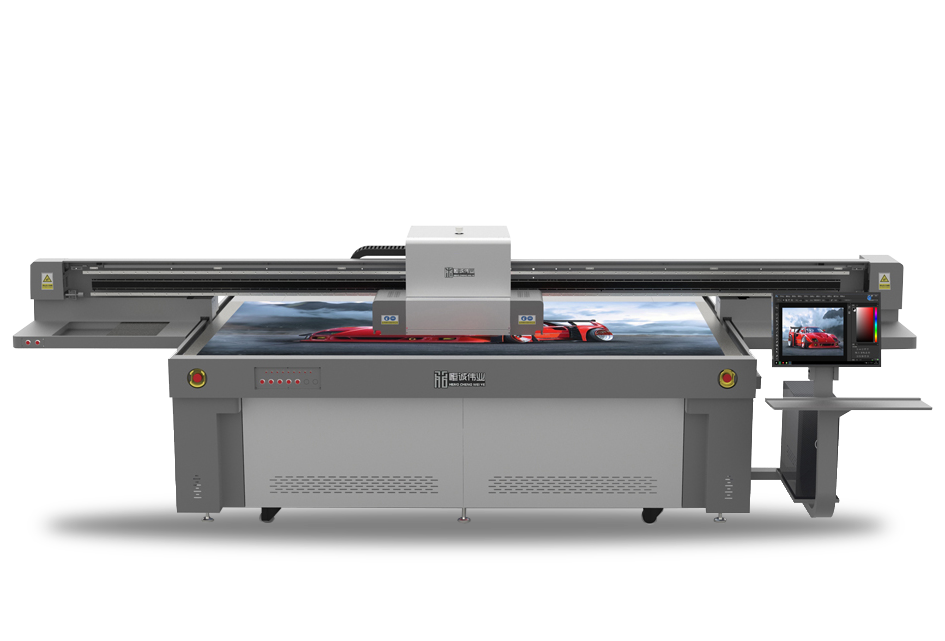

Digital UV Printing Machine

Hengcheng Digital UV Printing Machine features powerful functions such as color printing, embossed printing, UV varnish printing, etc. Its versatility is remarkable, and it is not only limited to these functions. The application scope of the Digital UV Printing Machine is extremely wide, suitable for printing on materials like metal, glass, wood, and more, making it suitable for material production across various industries.

The advantages of the Digital UV Printing Machine lie in its ability to achieve high-resolution and durable printing on different types of materials, providing innovative solutions for diverse industries. This UV printer can print 12-15 square meters of material per hour.

If you want to learn more about the features of the UV printer, please contact us immediately. We are here to customize professional solutions for you!

- Parameter

- Features and Benefits

- Video

| Model number | SPB-DH1 | SPB-DH2 |

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm |

| Weight | 21 kg | 22 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

Describe

The UV printer has a number of cutting-edge parts that are expertly constructed. Accurate printing is made possible by the use of a magnetic levitation linear motor, which guarantees smooth and accurate linear motion. The printing platform is guaranteed consistent support by the sturdy and solid base provided by the Fenggang precision-milled steel beam. Because it is a strong light source, the high-power UV LED lamp can cure UV inks quickly, increasing printing efficiency.

The quiet and seamless motion made possible by the Japanese THK silent guide rails improves the printing experience as a whole. Structural integrity is provided by the integrated all-steel frame, which keeps everything stable throughout intricate printing procedures. The endurance of the printer is increased by the installation of an Eges Tank drag chain, which guarantees the safe and effective management of cables.

Printing outcomes are exact and dependable when segmented vacuum adsorption platforms are paired with precision servo motors. Using ball screws of the highest caliber from research further improves motion control accuracy. With its collision-resistant construction, the nozzle guards against any damage, demonstrating a well-considered design to increase the printer’s longevity.

For this UV printer, the industrial-grade print head’s cutting-edge features deliver exceptional print quality and performance. These parts work together to provide a cutting-edge UV printing device that is dependable for a range of printing applications and excels in accuracy, efficiency, and durability.

Table of Contents

Features and Benefits

- Print Head Model and Quantity: Utilizing Ricoh G5/G6 print heads, equipped with three heads, providing users with an efficient and precise inkjet experience.

- Ink Configuration and Color Management: Supports multiple ink supply methods, including W+CMYK and W+CMYK+V, with built-in ICC color management curves to ensure accurate and vibrant color reproduction.

- Print Size and Precision: Offers large-format printing with dimensions of 2500mm in width and 1300mm in length, combined with high printing precision to guarantee outstanding print quality.

- Image Support and Resolution: Compatible with various image formats, including TIFF (RGB/CMYK), AI, PDF, EPS, JPEG, and provides different resolution options such as 720900DPI/7201200DPI/720*1800DPI.

- Work Table and Material Thickness: Features an aerospace aluminum vacuum adsorption platform to securely hold printing materials, accommodating different material thicknesses.

- Power Consumption and Power Requirements: High energy efficiency, consuming only 1-1.5 kWh per hour, with a rated voltage of AC220V(+10%) at 50Hz and a power requirement of P:3500W (mainframe).

- Environmental Friendliness and Certification: Complies with environmental standards, emitting no VOC from ink, and certified by SGS and MDS, reflecting a commitment to environmental responsibility.

- Equipment Structure and Net Weight: Constructed with an all-steel mainframe structure, precision-milled and tempered steel beams, ensuring a robust equipment structure with a net weight of 1500KG.

- Drive Configuration: X-axis employs a magnetic levitation linear motor and THK silent guide rails, while the Y-axis utilizes precision motors, lead screws, and dual linear guides for precise and smooth motion control.

- Operating Environment and Temperature/Humidity: Adaptable to a wide range of environments, operating temperature of 20°C32°C, humidity of 4070%.

- ColorGate RIP Support: Equipped with professional-grade software such as ColorGate RIP/PP/PF/RIP, providing additional printing options and control.

- Equipment Size: Overall dimensions of 4230mm2050mm1310mm (lengthwidthheight), featuring a compact structure for space efficiency.

About UV Printer Guide

1.Learn about SuperbMelt UV Printer

SuperbMelt is a leading UV printer manufacturer in China, equipped with professional technology and impeccable after-sales service. As a UV printer manufacturer, we assist customers in printing and imaging materials of various textures, ensuring the completion of the final material production for our clients.

SuperbMelt’s printers can achieve a maximum printing speed of 12-15 square meters per hour. For information regarding the application industries and other parameters of our UV printers, feel free to contact SuperbMelt.

1.1Usage Method of UV Printer

Ensure the UV printer is placed on a stable and flat surface.

Connect the printer to a power source and turn it on.

Ensure the UV lamp is working correctly.

Loading Printing Material:

Prepare the printing material, whether it’s paper, plastic, wood, or another suitable substrate.

Adjust the media settings on the printer to match the type and size of the printing material.

Loading Ink:

Check the ink levels in the UV ink cartridges and refill or replace them if necessary.

Make sure to use compatible UV inks for the printer.

Software Setup:

Install the necessary printer drivers and software on your computer.

Open the design or image you want to print using the UV printer software.

Adjust the print settings, including size, resolution, and color options.

Printing:

Place the printing material on the printer bed or tray.

Adjust the printing settings on the printer control panel or software.

Start the printing process. The UV printer will deposit ink directly onto the material.

Monitor the printing process to ensure quality.

Curing:

Once the printing is complete, the printed material may need to go through a curing process.

UV printers use ultraviolet light to cure or dry the ink quickly. Ensure that the UV lamp is functioning correctly during this step.

Post-Processing:

After curing, inspect the printed material for quality.

Depending on the application, additional post-processing steps may be required, such as coating or laminating.

Maintenance:

Regularly clean the print head, ink nozzles, and other critical components to maintain optimal performance.

Follow the manufacturer’s guidelines for routine maintenance tasks.

1.2Operating Principle

The working principle of a UV printer involves three key steps:

inkjet printing through the nozzles, UV ink curing, and precise positioning. By controlling the voltage within the print head, UV ink is accurately sprayed onto the surface of the substrate to create the desired image. A small print head typically contains thousands of nozzles, allowing precise control of ink ejection. Subsequently, UV lamps emit ultraviolet waves, reacting with the photosensitive curing agent in the UV ink to rapidly solidify the ink molecules on the surface of the material, achieving instant drying without the need for traditional baking or air-drying processes. Finally, UV printers utilize precise positioning principles, including grating decoders, servo motors, and the lifting function of the print head, to achieve accurate printing on different materials and shapes. This series of principles enables UV printers to accomplish high-speed and high-precision printing processes

2.Applications of UV Printers in Industries

A revolution in printing technology is being driven by the extensive use of UV printers in a variety of sectors. These printers are the go-to tools for manufacturers, designers, and artists due to their outstanding performance. UV printers offer high-quality, long-lasting, and accurate printing on a variety of materials, opening up new opportunities for enterprises and the creative sector. These applications range from personalized product marks in manufacturing to outdoor advertising and interior design in the advertising industry. Using their UV curing technology, these printers can print on a variety of materials, such as ceramics, wood, metal, and plastic, with instantaneous ink drying. In addition to increasing production efficiency, this cutting-edge printing technique makes important advancements in image quality and durability. UV printers are used for purposes beyond printing; they allow users a completely new level of freedom and creativity, hence redefining the creative and production paradigm.

2.1How to Choose a UV Printer

A UV printer requires consideration of various factors to ensure it meets your specific needs and requirements. Here are key considerations to guide you in selecting the right UV printer:

Printing Size and Format:

Determine the maximum size and format of the prints you’ll be producing. UV printers come in various sizes, so choose one that accommodates your intended output dimensions.

Printing Speed:

Consider the speed of the UV printer, especially if you have high-volume printing needs. Faster printers are suitable for large-scale production.

Ink Configuration:

UV printers use different ink configurations, including CMYK, CMYK+W, and CMYK+Lc+Lm+W. Choose an ink configuration that aligns with the color requirements of your prints.

Print Head Technology:

The type of print head influences print quality and speed. There are different technologies like piezoelectric and thermal inkjet. Research and choose a printer with a print head that meets your expectations.

Substrate Compatibility:

Ensure the UV printer is compatible with a variety of substrates. Whether you’re printing on rigid materials like wood and metal or flexible materials like PVC and acrylic, choose a printer that suits your application.

Curing System:

UV printers use either LED or mercury vapor lamps for curing. LED curing is energy-efficient and allows for printing on heat-sensitive materials. Consider the curing system based on your printing requirements.

Ease of Use:

Look for a UV printer with user-friendly features and an intuitive interface. Ease of use is essential for efficient operation, especially if you’re new to UV printing.

Maintenance Requirements:

Consider the maintenance needs of the UV printer. Some printers may require more frequent maintenance, affecting downtime. Choose a printer with manageable maintenance requirements.

Software Compatibility:

Ensure the UV printer’s software is compatible with your design and workflow software. Compatibility ensures a seamless integration into your existing processes.

Budget Considerations:

Set a budget for your UV printer purchase. Consider not only the upfront cost but also ongoing expenses such as ink and maintenance. Choose a printer that offers a balance between features and cost.

2.2Why Do You Need a UV Printer?

UV printers are vital for a variety of businesses because of their special qualities:

Extensive Material Selection: UV printers exhibit remarkable adaptability as they can print on a wide range of materials, including metal, glass, ceramics, plastic, wood, leather, and more.

Superior Printing: UV printers are ideal for applications requiring exceptional print quality, such art, advertising, and packaging, since they can produce high resolution, fine pictures, and legible text.

Instant Curing: When UV ink is exposed to light, it cures quickly, removing the need for a drying period and increasing production efficiency.

Broad Color Gamut: UV printers that use UV inks have a wider color gamut, which makes it possible to produce images with richer, more brilliant colors.

Versatility: UV printers are more applicable since they can print flat, in three dimensions, and on stiff materials, among other things.

Eco-friendly: UV printing with solvent-free UV inks helps to protect the environment by lowering the amount of volatile organic compounds (VOCs) released into the air.

Short Runs and Customization: UV printers can satisfy the needs of personalized printing by being used for small runs, a variety of items, and customized manufacturing.

Durable Prints: UV-printed patterns are perfect for outdoor signs and advertising because they dry rapidly, producing prints that are both abrasion-resistant and durable.

FAQ about UV Printer

A Digital UV Printing Machine is a modern printing technology that uses ultraviolet (UV) light to instantly cure or dry inks as they are printed onto various substrates. It offers high-quality, versatile, and efficient printing solutions.

Digital UV Printing Machines are versatile and can print on a wide range of materials, including metal, glass, wood, plastics, ceramics, and more.

UV printing differs from traditional methods by using UV-curable inks that dry instantly when exposed to UV light. This eliminates the need for drying time and allows for printing on non-absorbent surfaces.

UV printing offers several advantages, including instant curing, vibrant and durable prints, the ability to print on various materials, and environmental benefits due to the absence of solvents.

Yes, UV printing is considered environmentally friendly as it produces minimal VOC emissions, reduces waste, and eliminates the need for additional drying processes, contributing to a more sustainable printing solution.

Yes, Digital UV Printing Machines can produce full-color prints with high resolution, providing vibrant and detailed images.

Common file formats such as TIFF, AI, PDF, EPS, and JPEG are compatible with Digital UV Printing Machines, ensuring flexibility in design and artwork.

Yes, UV printing uses UV-curable inks that contain photoinitiators. These inks cure rapidly when exposed to UV light, resulting in durable and scratch-resistant prints.

Yes, UV prints are known for their durability and resistance to outdoor elements, making them suitable for various outdoor applications.

Regular maintenance includes cleaning printheads, checking and replacing UV lamps, and ensuring proper functioning of other components. Manufacturers provide guidelines for routine maintenance.

UV printers are versatile and can print on a wide range of materials, it’s essential to note that they may not be suitable for printing on absolutely everything. The effectiveness of a UV printer depends on factors such as the material’s texture, surface finish, and composition.